CINTROPUR Filter(Manual)

Made entirely from first-quality synthetic material, CINTROPUR filters

are perfectly suitable for food products and drinking water.

The CINTROPUR vane transforms the liquid flow into a centrifugal spin

by throwing the larger particles down into the lower bowl, according to

the chosen filter sleeve micron-size.

Protection of industrial as well as residential and agricultural installations

by filtering the solid particles (earth, sand, rust, etc,…) suspended in the

water.

Advantages & Uses

-

Advantages of our CINTROPUR Filter System

01 Preprocessing filter is applicable broadly from industrial to household (Including hotel, restaurant, school, building etc)

02 Maximization of big foreign substance applied to “CENTRIFUGAL SPIN”.

03 Strong pressure resistance by using “Polyphosphate”, and it can be used up to 60℃

04 Visually check the lifespan and operation of the filter through transparent container

05 Stable flow rate supply by less pressure loss

06 Recyclable by using nylon filter (saving on consumable expenses)

07 Adoption of a valve to easily remove particulate substances (Industrial use)

Large capacity

One sheet of 25micron filter and Black Spanner is included on first purchase.

Technical DATA

| Filter type | NW 18 | NW 18 | NW 18 | NW 32 TE | |

|---|---|---|---|---|---|

| Diameter of pipe | 2″ | 2½” | 3″ | 2″ | |

| Average flow rate: | ㎥/h | 18 | 25 | 32 | 2* |

| Δp=0.2bar | 2.8psi gpm | 79 | 110 | 141 | 9* |

| Working pressure: | bar | 10 | 10 | 10 | 10 |

| psi | 145 | 145 | 145 | 145 | |

| Max. operating pressure: | bar | 16 | 16 | 16 | 16 |

| psi | 232 | 232 | 232 | 232 | |

| Max. operating t˚ | 50˚C | 50˚C | 50˚C | 50˚C | |

| 122˚F | 122˚F | 122˚F | 122˚F | ||

| Weight: | kg | 6.4 | 7 | 7.4 | 5.6 |

| pounds | 14.11 | 15.43 | 16.31 | 12.35 | |

| Standard filter sleeve | 25μ | 25μ | 25μ | - | |

| Volume of the bowl: | ltr | - | - | - | 4.85 |

| US Gal | - | - | - | 1.28 | |

| Filtration: | ㎠ | 1288 | 1288 | 1288 | - |

| Surface | Sq inches | 199.64 | 199.64 | 199.64 | - |

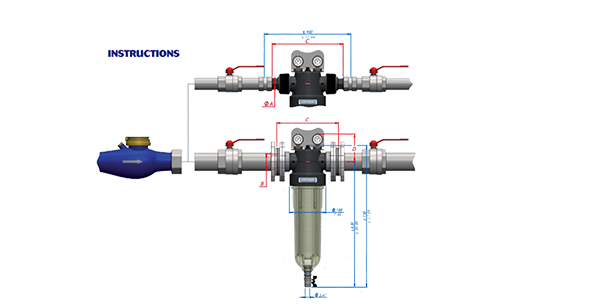

DIMENSION

|

Sides en | A (Ø)) | B | C | D |

|---|---|---|---|---|---|

| NW500 | 2" | DN50 | 363(14.29) | ±140(±5.51) | |

| NW650 | 21/2" | DN65 | 304(11.97) | ±140(±5.51) | |

| NW800 | 3" | DN80 | 313(12.32) | ±140(±5.51) | |

| NW500 TE | 2" | DN50 | 363(14.29) | ±86(±3.39) |

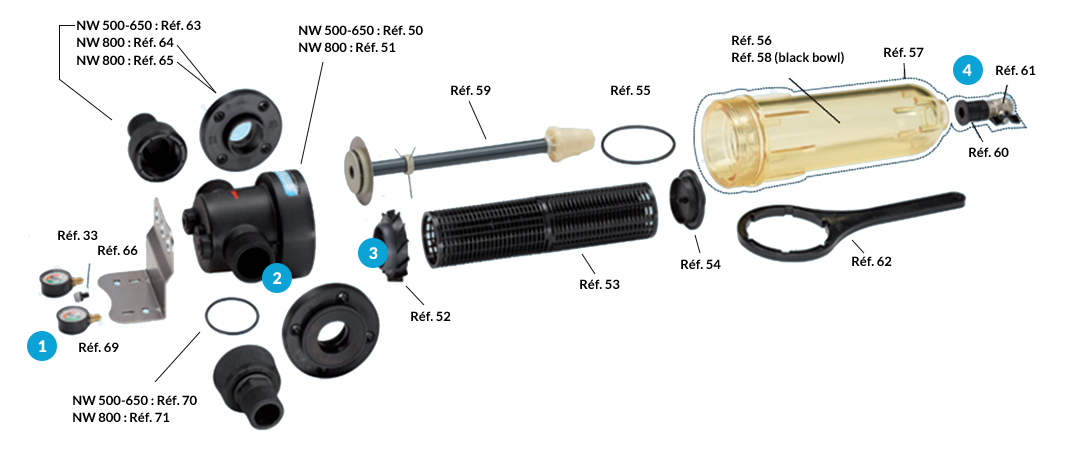

Spare parts

Filters(5 sheets / 1 set)

Non washable5μ / 10μ / 25μ / 50μ / 100μ

Washable150μ

Activated carbon (carton of 3.4 liters / 0.9 US Gal) * Carbon filling amount by model

NW 25TE0.85 l / 0.22 US Gal (4 refills)

Washable1.70 l / 0.45 US Gal (2 refills)

-

1 Pressure gauges 0-20 bar 1/4“

-

Indicate the system pressure. Filter sleeves are to be changed

at ΔP of 2 bar or at least 3 times a year

-

2 Head connector thread

-

- Metric 76 for 500/650 heads

- Metric 88 for 800 heads g

Use only CINTROPUR fittings/flanges

-

3 Centrifugal vane

-

It creates a cyclonic effect on the intake water flow which precipitates the large particles

at the bottom of the filter bowl. The inner/outer pre-moulded joints and the set screw

will ensure optimum sealing

-

4 Drain valve, ¾’’

-

Allows to evacuate the impurities deposited on the bottom of the bowl as a result

of the cyclonic action of the centrifugal vane

-

A Pressure gauges 0-20 bar 1/4“

To be placed between the flange and counter flange.

For NW650 (Ref. 67) – for NW800 (Ref. 68) -

B Wall fixation

Stainless steel wall bracket is to be attached to the filter head

with two locking nuts. Same model for all industrial filters. -

C Black Bowl

Stainless steel wall bracket is to be attached to the filter head

with two locking nuts. Same model for all industrial filters. -

D TE device

Device inside the TE filter: used for water treatment by activated carbon

or polyphosphates; may also be placed in the NW650 and NW800.